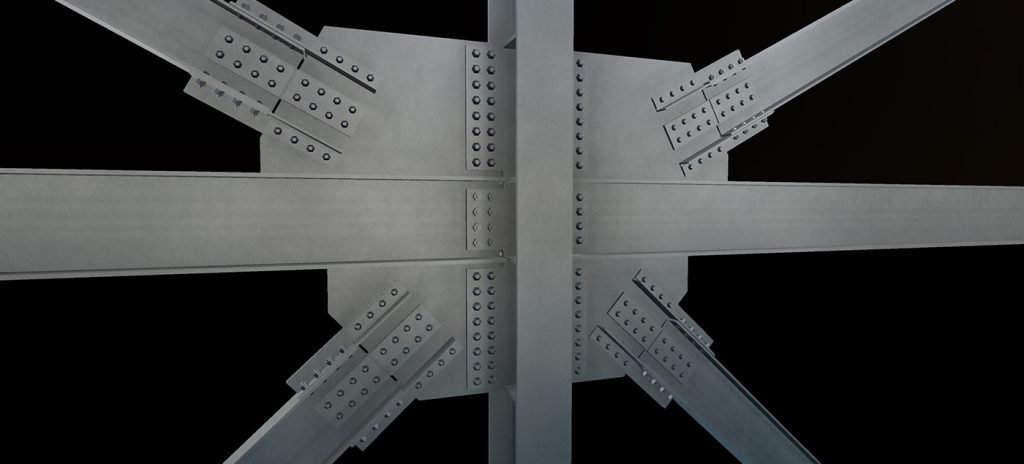

Connection design in steel detailing is a critical aspect of structural steel construction. It involves designing and detailing connections between steel members to ensure the stability and safety of the structure. Here are some key aspects of connection design in steel detailing:

- Types of Connections

1. Bolted Connections: These connections use bolts to join steel

members. They can be designed as slip-critical or bearing type

connections.

2. Welded Connections: These connections use welds to join steel

members. They can be designed as complete joint penetration (CJP)

or partial joint penetration (PJP) welds.

- Design Considerations

1. Symmetry: Connections should be designed to be symmetrical to

avoid eccentricity.

2. Slip Resistance: Slip-critical bolted connections should be designed

to resist slip at service loads and bearing failure at strength limit

states.

3. Weld Throat Thickness: Weld throat thickness should be designed

to resist the applied loads.

4. Material Grades: The material grades of the steel members and

connections should be compatible.

- Software Used

1. Ram Connection: A software used for connection design and analysis.

2. Idea Statica: A software used for connection design and analysis.

3. Limcon: A software used for connection design and analysis.

4. Descon Brace: A software used for connection design and analysis.

5. Risa Connection: A software used for connection design and analysis.

- Benefits of Proper Connection Design

1. Safety: Proper connection design ensures the stability and safety of

the structure.

2. Efficiency: Well-designed connections can reduce fabrication and

construction costs.

3. Reliability: Proper connection design can minimize the risk of failure

at joints.