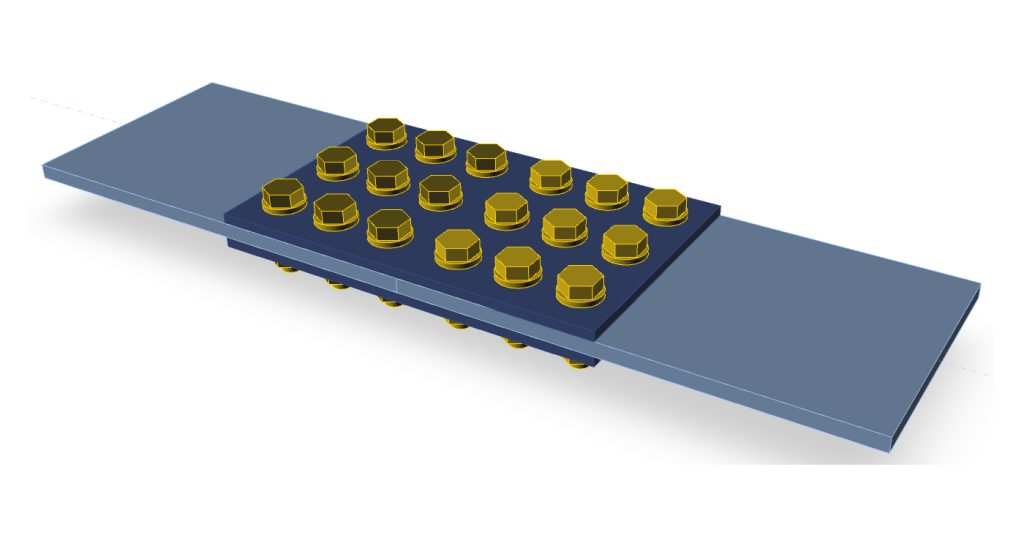

Slip-critical connections in steel detailing and connection design refer to bolted connections that are designed to resist slip between the connected parts under service loads.

Key Characteristics

1. Friction-based resistance: Slip-critical connections rely on the friction between the connected parts to resist slip.

2. High-strength bolts: Slip-critical connections typically use high-strength bolts, such as A325 or A490 bolts.

3. Clean and prepared surfaces: The faying surfaces (surfaces in contact) must be clean and free of dirt, oil, and other substances that could reduce friction.

Design Considerations

1. Slip resistance: The connection must be designed to resist slip under service loads, taking into account the friction coefficient, bolt tension, and surface conditions.

2. Bolt tension: The bolts must be tightened to the specified tension to ensure adequate friction between the connected parts.

3. Surface preparation: The faying surfaces must be properly prepared to ensure adequate friction.

Applications

1. High-strength applications: Slip-critical connections are often used in high-strength applications, such as bridges, high-rise buildings, and industrial structures.

2. Fatigue-sensitive applications: Slip-critical connections are used in applications where fatigue is a concern, such as in structures subject to repeated loading and unloading.

3. Dynamic loading: Slip-critical connections can be used in applications where dynamic loading is expected, such as in structures subject to wind or seismic loads.

Benefits

1. Improved structural performance: Slip-critical connections can improve the structural performance of a building or bridge by reducing the risk