Building Information Modelling (BIM) is a digital representation of the physical and functional characteristics of a building. In the context of steel detailing, fabrication, and erection, BIM plays a crucial role in coordinating with other trades. Here’s how:

A) Benefits of BIM in Steel Construction

1. Improved Coordination: BIM enables steel detailers, fabricators, and erectors to coordinate with other trades, such as MEP (mechanical, electrical, and plumbing) and architectural teams.

2. Clash Detection: BIM software can detect clashes between different trades, reducing errors and conflicts during construction.

3. Enhanced Collaboration: BIM facilitates collaboration among stakeholders, including architects, engineers, contractors, and fabricators.

4. Increased Accuracy: BIM models can be used to generate accurate shop drawings, reducing errors and rework.

B) BIM in Steel Detailing

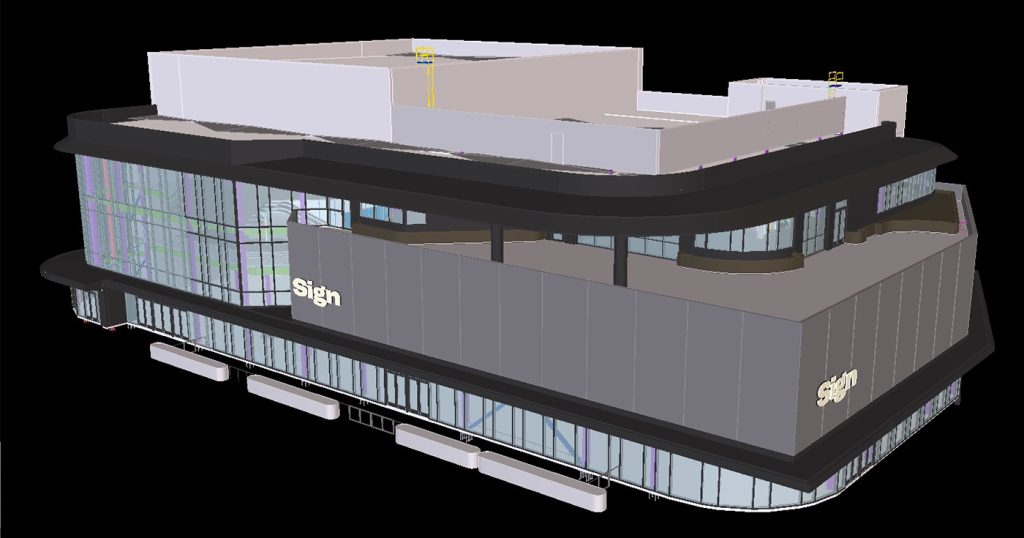

1. 3D Modelling: BIM software, such as Tekla or Autodesk Advance Steel, can be used to create detailed 3D models of steel structures.

2. Clash Detection: BIM software can detect clashes between steel members and other trades, such as MEP systems.

3. Interoperability: BIM models can be shared with other stakeholders, ensuring that all parties are working with the same information.

C) BIM in Fabrication and Erection

1. Digital Fabrication: BIM models can be used to drive CNC machines and other fabrication equipment, reducing errors and increasing efficiency.

2. Erection Planning: BIM models can be used to plan and simulate the erection process, reducing risks and improving safety.

3. Site Logistics: BIM models can be used to plan and manage site logistics, including material delivery and storage.

D) Specific Benefits for MEP Trades

1. Routing and Placement: BIM models can be used to route and place MEP systems, considering the steel structure and other trades.

2. Clash Detection: BIM software can detect clashes between MEP systems and steel members, reducing errors and conflicts.

3. Prefabrication: BIM models can be used to prefabricate MEP components, such as pipe spools and ductwork.

E) Specific Benefits for Architectural Trades

1. Design Coordination: BIM models can be used to coordinate architectural design with steel fabrication and other trades.

2. Visualization: BIM models can be used to visualize the building design and identify potential issues.

3. Material Quantification: BIM models can be used to quantify materials and reduce waste.

F) Best Practices for BIM Implementation

1. Standardize Processes: Establish standardized processes for BIM implementation, including data exchange and collaboration protocols.

2. Train Personnel: Provide training for personnel on BIM software and processes.

3. Collaborate with Stakeholders: Collaborate with stakeholders, including architects, engineers, and contractors, to ensure that all parties are working with the same information.

By leveraging BIM technology, steel detailers, fabricators, and erectors can improve coordination, reduce errors, and increase efficiency, ultimately delivering projects on time and within budget.