- Best Practises For Creating Accurate Shop Drawings

General Best Practice Use precise measurements: Ensure that all measurements are accurate and consistent with the project requirements.2. Follow industry standards: Adhere to relevant industry standards, such as AISC (American Institute of Steel Construction) or BS (British Standards).3. Use clear and concise notation: Use standard notation and abbreviations to avoid confusion.4. Verify and validate: Double-check… Read more: Best Practises For Creating Accurate Shop Drawings

General Best Practice Use precise measurements: Ensure that all measurements are accurate and consistent with the project requirements.2. Follow industry standards: Adhere to relevant industry standards, such as AISC (American Institute of Steel Construction) or BS (British Standards).3. Use clear and concise notation: Use standard notation and abbreviations to avoid confusion.4. Verify and validate: Double-check… Read more: Best Practises For Creating Accurate Shop Drawings - Slip Critical Connections

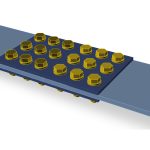

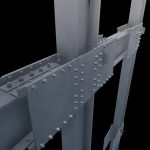

Slip-critical connections in steel detailing and connection design refer to bolted connections that are designed to resist slip between the connected parts under service loads. Key Characteristics 1. Friction-based resistance: Slip-critical connections rely on the friction between the connected parts to resist slip.2. High-strength bolts: Slip-critical connections typically use high-strength bolts, such as A325 or… Read more: Slip Critical Connections

Slip-critical connections in steel detailing and connection design refer to bolted connections that are designed to resist slip between the connected parts under service loads. Key Characteristics 1. Friction-based resistance: Slip-critical connections rely on the friction between the connected parts to resist slip.2. High-strength bolts: Slip-critical connections typically use high-strength bolts, such as A325 or… Read more: Slip Critical Connections - Moment Connections

Moment connections in steel detailing and connection design refer to the connections between beams and columns that are designed to resist moments (rotational forces) and transfer loads between the connected members. Types of Moment Connections 1. Fully Restrained (FR) Connections: These connections provide full continuity between the connected members and are designed to resist moments,… Read more: Moment Connections

Moment connections in steel detailing and connection design refer to the connections between beams and columns that are designed to resist moments (rotational forces) and transfer loads between the connected members. Types of Moment Connections 1. Fully Restrained (FR) Connections: These connections provide full continuity between the connected members and are designed to resist moments,… Read more: Moment Connections - BIM and how it helps in coordinating with other Trades

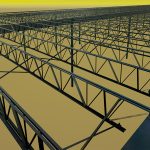

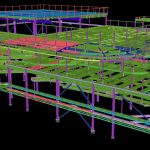

Building Information Modelling (BIM) is a digital representation of the physical and functional characteristics of a building. In the context of steel detailing, fabrication, and erection, BIM plays a crucial role in coordinating with other trades. Here’s how: A) Benefits of BIM in Steel Construction1. Improved Coordination: BIM enables steel detailers, fabricators, and erectors to… Read more: BIM and how it helps in coordinating with other Trades

Building Information Modelling (BIM) is a digital representation of the physical and functional characteristics of a building. In the context of steel detailing, fabrication, and erection, BIM plays a crucial role in coordinating with other trades. Here’s how: A) Benefits of BIM in Steel Construction1. Improved Coordination: BIM enables steel detailers, fabricators, and erectors to… Read more: BIM and how it helps in coordinating with other Trades - Bolted Connections vs Welded Connections

Bolted connections and welded connections are two common methods used to join steel members in steel fabrication. Here’s a comparison of the two: 2. Disadvantages: – May require more material and labour for bolt installation – Can be prone to loosening over time – May not provide the same level of structural integrity as welding… Read more: Bolted Connections vs Welded Connections

Bolted connections and welded connections are two common methods used to join steel members in steel fabrication. Here’s a comparison of the two: 2. Disadvantages: – May require more material and labour for bolt installation – Can be prone to loosening over time – May not provide the same level of structural integrity as welding… Read more: Bolted Connections vs Welded Connections