Structural Steel Detailing

Anchor bolts and base plates

- Preparation of anchor bolt setting plans, including layouts, dimensions and installation details for all foundations and pedestals.

- Shop drawings for anchor bolts and levelling plates, indicating bolt sizes, embedment depths, edge distances, plate sizes, tolerances and all relevant notes.

Embeds and miscellaneous steel

- Preparation of embed layouts and details for all required embed plates, angles and other embeds in concrete elements.

- Shop drawings for embed plates and angles, including plate sizes, stiffeners (if any), weld symbols, anchors and material specifications.

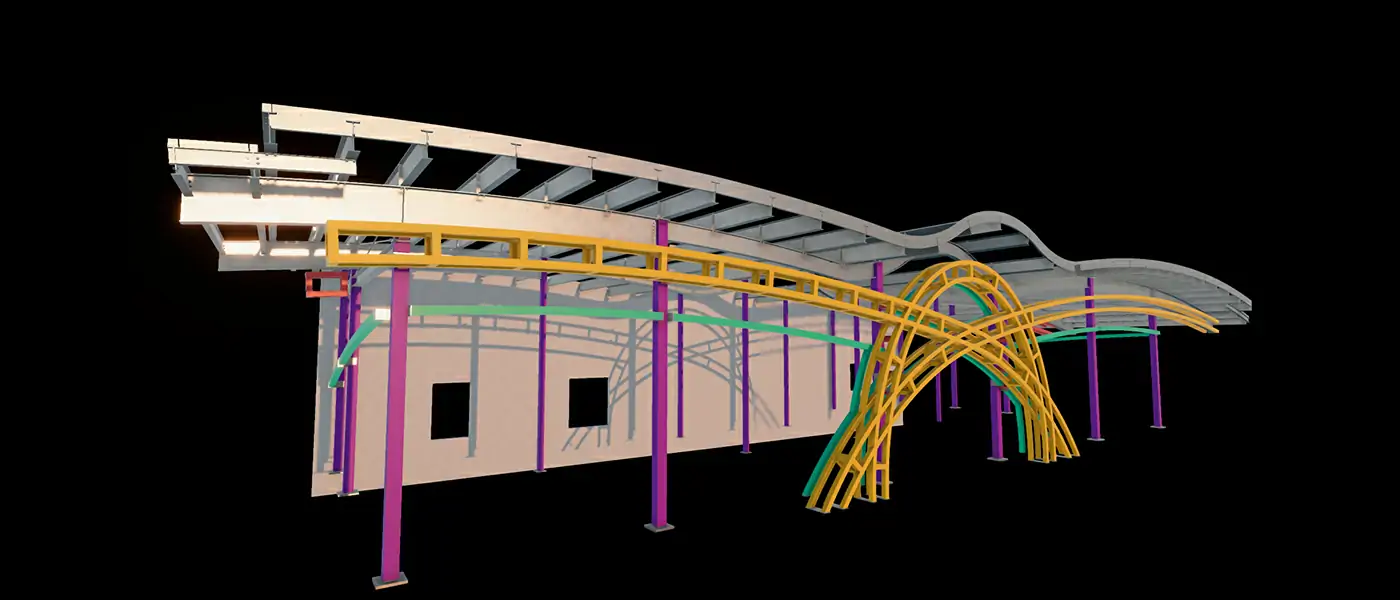

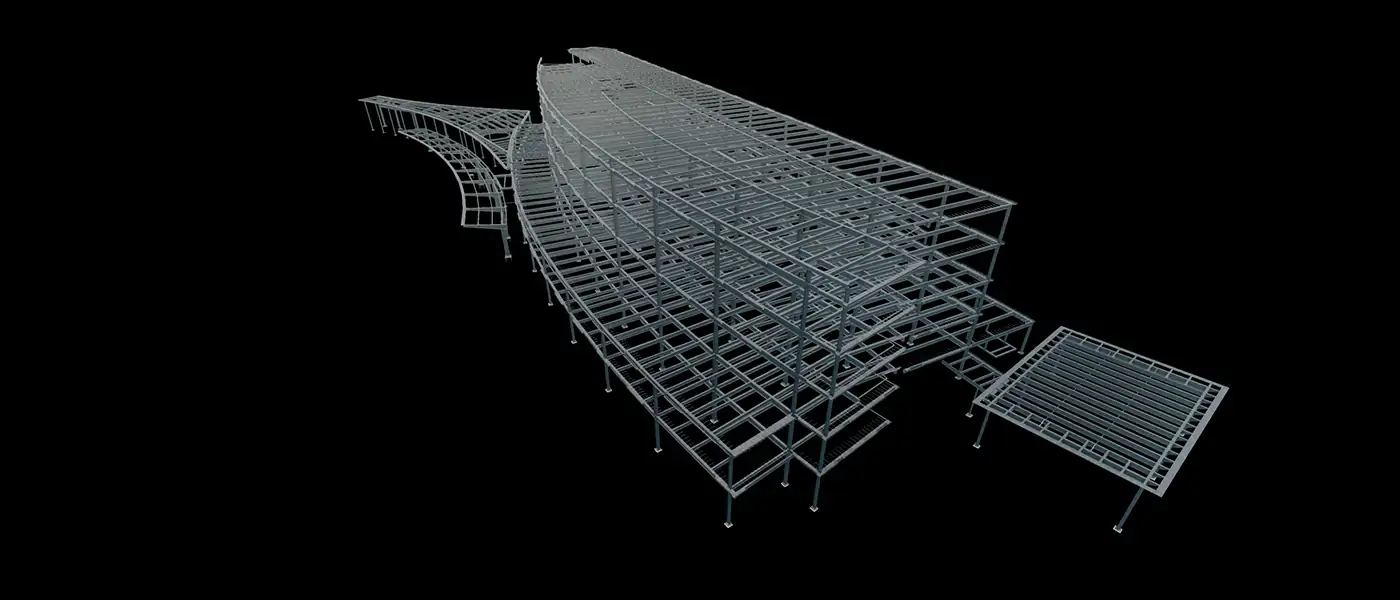

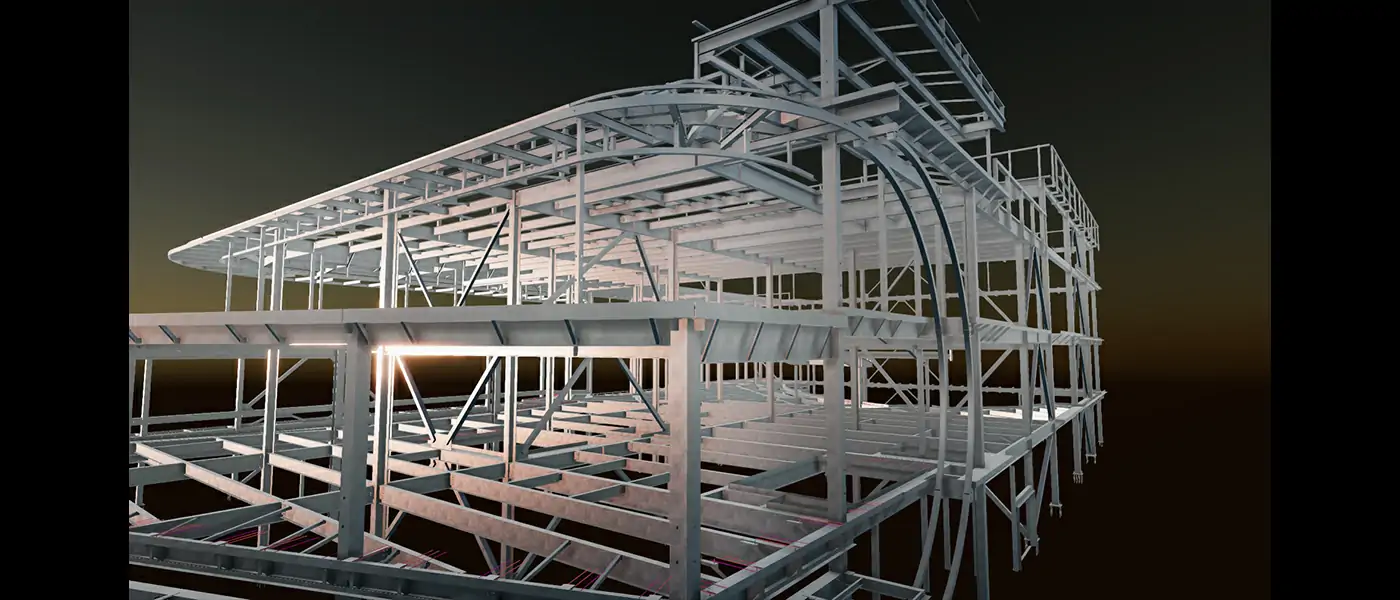

Erection and framing plans

- Erection/framing plans for all floor levels and roof, showing member sizes, marks, elevations, and framing geometry.

- Shop drawings for all primary and secondary steel members (columns, beams, bracings, rafters, joists, etc.), including member cuts, copes, holes, and connection interfaces.

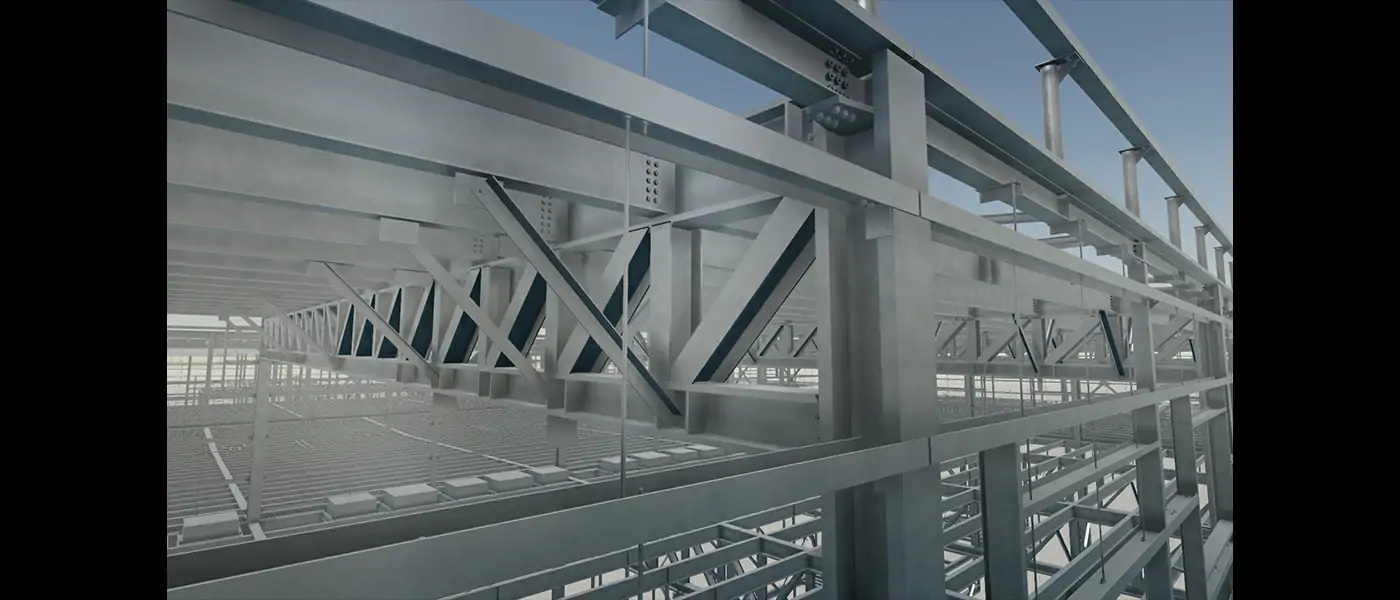

Elevations, bracing and sections

- Elevation views showing all vertical and horizontal bracing members with their orientations, sizes, locations and connection details.

- Sections and detailed views providing field information, including field bolting, field welding, erection aids and any special installation notes.

Reports and deliverables

- Material take off and member list reports for all structural and miscellaneous steel items.

- CNC/NC and DXF files for plate and member fabrication, as required by the fabricator.

- KSS (or equivalent) data files for interoperability with fabrication and management software.

- Shop and field bolt lists, including bolt sizes, grades, quantities and usage locations.

If you share your target project type (PEB, conventional steel, industrial, etc.) and any code or client requirements, this script can be further tailored into a formal “Scope of Detailing Services” section for your proposals or contracts.